SF Series machining centre

Confirm if additional costs apply

SF Series machining centre : $320,000 - $390,000 AUD ($352,000 - $429,000 Inc. GST)

- SF series machines, with typical VW products features of rigid structure and high precision, are designed with direct-driven X-Y transmission device and torque enlarger unit on X-axis, increase the X-Y moving accuracy and offer the combination control of speed and precision.

- Twin Hydraulic cylinders plus pressured nitrogen accumulator balancing design provides smooth & accurate feeding performance. Z-axis can reach 0.5G acceleration and keep a holding position at power failure.

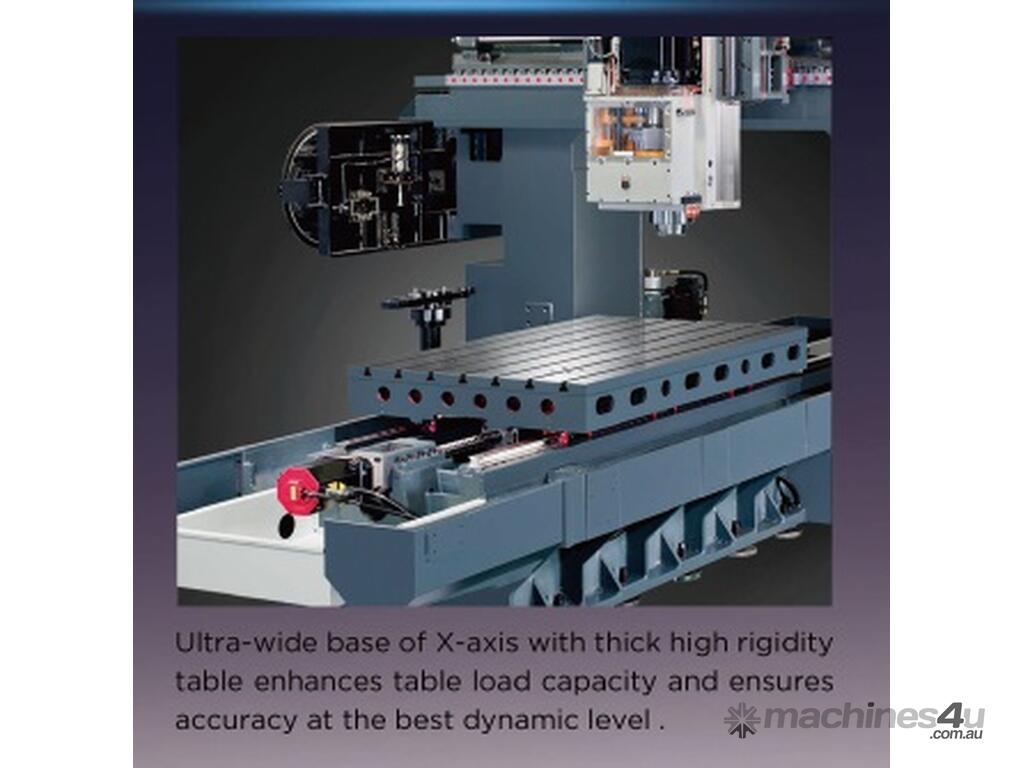

- Heavy duty roller ways on X-Y axis contain the advantages of low friction and high stiffness.

- High stiffness light-weight table design, ensures high acceleration/deceleration when loading.

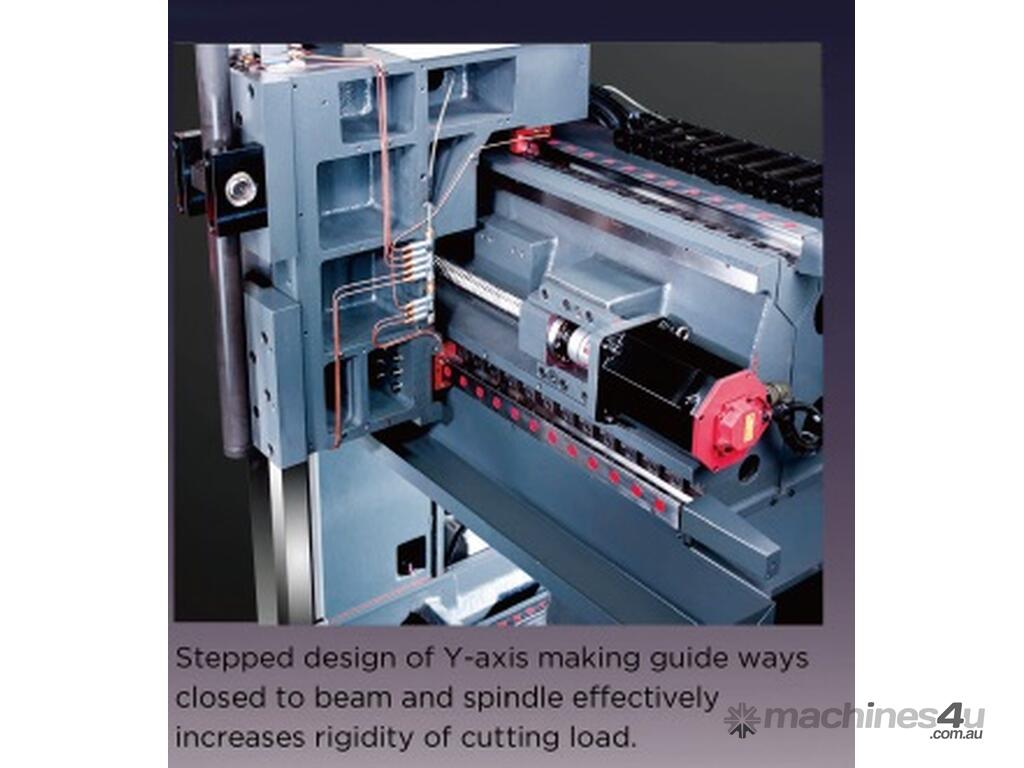

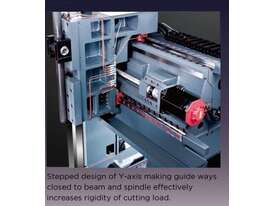

- Y-axis upper roller way is positioned on the top of beam at max. span design offers strong supporting.

- Torque enlarger unit on X-axis increases the transmission torque and ensures the transmission accuracy.

STANDARD ACCESSORIES & FUNCTIONS:

Fanuc 0i MF controller

10.4" Color Monitor

Manual Guidei Conversational Programming

6,000 rpm 2-step gear spindle (Box way)

Spindle and gear box cooling system

Twin hydraulic cylinders with pressure air assistance balancing system

32 tool magazine with arm type ATC

Centralized auto lubrication system

Independent lubrication oil collector for 3 axes(X/Y/Z)

Enclosure splash guard(without roof)

Working light

3-color signal lamp

Air blast through spindle

Moveable manual pulse generator

Wash gun & pneumatic interface

RS232 interface

Absolute pulse coder feedback

Vision Wide VW-FX graphical user interface

Coolant system (Ring & Nozzle)(only for box way spindle)(without AC interface)

Heat exchanger for electrical cabinet

Twin chip screws on table side

Caterpillar type chip conveyor

Foundation pads & bolts kits

Tool kits

Operation manual, PLC & electrical circuit diagram

OPTIONAL ACCESSORY & FUNCTION:

4,000/4,500/8,000 rpm 2-step gear spindle

8,000 /10,000 rpm belt-driven spindle

18,000/24,000rpm Built-in spindle

10,000rpm direct-driven spindle

40T tool magazine

Coolant through tool holder interface

Coolant through spindle system

HEIDENHAIN linear scale feedback

200/300/400 mm higher column extension(Higher column 200mm extended only for SF-xx12 series)

Sub working table

Oil skimmer

Oil mist cooling device

Rotary table

Interface preparation for rotary table(Machine contains within the hose and oil tank)

3-axis manual pulse generator

Automatic tool length measurement

Automatic work piece measurement

Manual clamping heads: 90 degree / extended / universal

Semi-auto clamping heads:90 degree

Transformer

Chip cart

Z-axis retract function at power failure

Full enclosure splash guard

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print